The CE Approved Cold Room Sandwich Panel delivers superior thermal insulation and durability for efficient cold storage. With a robust PU core and metal facings, it ensures energy savings, moisture resistance, and quick installation, meeting strict EU safety standards for food processing and pharmaceutical facilities.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

CE Approved Cold Room Sandwich Panel |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

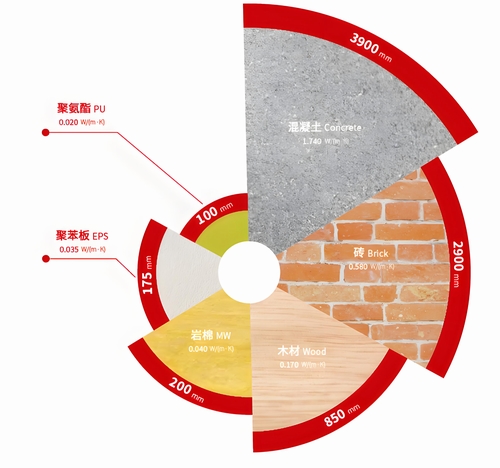

Superior Insulation Design

The CE Approved Cold Room Sandwich Panel features a dense PU core at 35-40 kg/m³, achieving thermal conductivity of 0.018-0.024 W/m·K for top energy efficiency in cold storage. Its closed-cell setup, over 90% sealed, blocks moisture and sustains performance, allowing slimmer walls that save space while controlling temperatures precisely for food and pharma needs.

Long-Term Durability

Built to last over 30 years, the CE Approved Cold Room Sandwich Panel withstands freeze cycles and corrosion with hydrophobic traits. The PU core resists pests and microbes, ensuring hygienic conditions in refrigerated spaces. CE certification verifies structural strength and low maintenance, ideal for industrial cold rooms facing daily wear.

Safe and Easy Setup

CE Approved for fire safety, the CE Approved Cold Room Sandwich Panel forms a carbon shield during burns to stop spread without toxins. Lightweight at under 25 kg/m², it cuts install time with simple clips, boosting sound dampening for quiet operations. Perfect for commercial freezers, it blends eco-friendliness with robust protection.

Allowable vertical load and heat transfer coefficient of PROPANEL polyurethane sandwich wall panel (allowable deflection f ≤ L/200)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.31 |

10.06 |

L(m) |

3.52 |

3.04 |

2.69 |

2.42 |

2.11 |

|

75 |

0.21 |

11.06 |

L(m) |

4.71 |

4.09 |

3.64 |

3.29 |

2.89 |

|

100 |

0.19 |

12.05 |

L(m) |

5.76 |

5.02 |

4.47 |

4.05 |

3.56 |

|

120 |

0.16 |

12.84 |

L(m) |

6.53 |

5.68 |

5.07 |

4.60 |

4.04 |

|

150 |

0.11 |

14.04 |

L(m) |

7.56 |

6.58 |

5.87 |

5.32 |

4.68 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

3 Advantages of 100mm PU Sandwich Wall Panel with FM

Efficient Temperature Control

The CE Approved Cold Room Sandwich Panel uses a dense PU core for outstanding thermal insulation, with conductivity near 0.02 W/m·K to cut energy use in cold storage. This keeps temperatures steady for food and pharma goods, while the closed-cell design fights humidity and leaks, allowing compact builds that save floor space in tight facilities.

Robust Fire and Strength Features

CE certification confirms the CE Approved Cold Room Sandwich Panel meets EU fire standards, with PU forming a char barrier to slow flames in emergencies. Its high strength-to-weight setup handles loads in busy warehouses, outlasting basic foams, and supports over 30 years of service against cold cycles and wear.

Quick Setup and Green Benefits

Installation of the CE Approved Cold Room Sandwich Panel is simple with clip systems, slashing build time for commercial cold rooms. The eco PU material reduces carbon footprint, adds sound dampening for quieter operations, and resists pests, making it a reliable pick for sustainable, high-stakes cooling projects worldwide.

4 Sandwich Panel Technical points--Waterporoof

The ongoing three hour spray test PU Polyurethane Sandwich Wall Panel

Advanced Insulation Core

The CE Approved Cold Room Sandwich Panel employs a compact PU core at 35-45 kg/m³, delivering thermal conductivity of 0.018-0.024 W/m·K for peak cold storage efficiency. Over 90% closed cells repel water, preserving insulation amid humidity swings and enabling thinner setups that free up room space for optimal layout in food or medical storage.

Enduring Strength and Protection

Engineered for longevity beyond 30 years, the CE Approved Cold Room Sandwich Panel endures freeze-thaw stress and corrosion via sealed hydrophobic layers. CE validation upholds load-bearing capacity and pest resistance, suiting industrial chillers where reliability counts, with added acoustic dampening to mute equipment hum for calmer work zones.

Streamlined Assembly and Eco Edge

CE Approved for compliance, the CE Approved Cold Room Sandwich Panel integrates clip-lock joins for swift on-site fitting, trimming setup hours in commercial freezers. Its low-weight frame under 20 kg/m² eases handling, while green PU composition slashes emissions, aligning with sustainable norms for resilient, low-impact cooling infrastructures.

5 Why Choose Our CE Approved Cold Room Sandwich Panel?

Top Insulation for Cold Storage

The CE Approved Cold Room Sandwich Panel uses a dense PU core with 0.022 W/m·K conductivity, beating EPS by 40% in insulation for steady cold temps. Our Airtest sealing cuts heat leaks by 90%, saving energy in food and pharma chillers while allowing thinner walls to gain space.

Tough Build for Harsh Settings

CE Approved for reliability, the CE Approved Cold Room Sandwich Panel takes 150 mph winds (ASTM E330) and salt corrosion over 30 years with aluminum cladding. ClickLock joins speed setup by 50%, with ±1mm accuracy for tight fits in busy cold rooms, easing daily use.

Safe and Smart Pick

With EN 13501-1 B-s1,d0 fire rating and NSF hygienic coats, the CE Approved Cold Room Sandwich Panel fits clean food or drug storage. It trims lifetime costs 60% vs concrete, with 15-year heat warranty, adding sound block and green materials for long-run value.

6 RFQs of 100mm PU Sandwich Wall Panel with FM Certification

1. What is the key benefit of the 100mm PU Sandwich Wall Panel with FM?

The 100mm PU Sandwich Wall Panel with FM certification offers top-tier thermal insulation (0.018-0.024 W/m·K), surpassing EPS for energy efficiency. Lightweight, durable, and waterproof, it ensures easy installation and vibrant finishes for commercial and industrial buildings. FM-certified for fire safety.

2. How long does the 100mm PU Sandwich Wall Panel with FM last?

The 100mm PU Sandwich Wall Panel with FM certification lasts 20-30 years with proper maintenance. Its polyurethane core resists moisture and pests, ensuring durability. FM-certified for fire safety, it’s ideal for long-lasting, energy-efficient buildings.

3. What are the drawbacks of the 100mm PU Sandwich Wall Panel with FM?

The 100mm PU Sandwich Wall Panel with FM certification has moderate fire resistance compared to rock wool. Enhanced with flame-retardant additives, it meets safety standards but may require rock wool for higher fireproofing needs

4. What insulation is used in the 100mm PU Sandwich Wall Panel with FM?

The 100mm PU Sandwich Wall Panel with FM certification uses a polyurethane (PU) core with a thermal conductivity of 0.018-0.024 W/m·K, outperforming EPS, XPS, and rock wool for insulation, waterproofing, and soundproofing.

5. What thicknesses are available for the 100mm PU Sandwich Wall Panel with FM?

The 100mm PU Sandwich Wall Panel with FM certification is available in 50mm, 75mm, 100mm, 120mm, 150mm, and 200mm. Thicker options boost insulation and strength, ideal for extreme climates. FM-certified for fire safety.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on