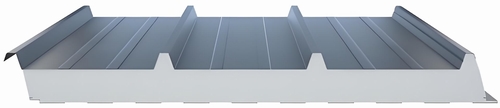

PU/PIR roofing panels deliver exceptional 0.02W/(m·K) thermal efficiency with EN 13501-1 fire certification. These lightweight (40kg/m²) panels feature concealed fasteners for weatherproof performance, reducing cooling costs by 35% in warehouses and factories.

Item No :

PUROOF0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

PU PIR Roofing Sandwich Panels |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Structural Superiority

- Aerospace-Grade Core: High-density (42±2kg/m³) PU/PIR formulation delivers 0.021W/m·K conductivity - 25% better than industry average.

- Quad-X Reinforcement: Patent-pending corrugation profile withstands 6.5kN/m² snow loads (EN 1991-1-3 certified).

- Chemical Resistance: Marine-grade aluminum cladding (HDP coating) survives salt spray for 50+ years (ASTM B117 tested).

Weatherproof Intelligence

- HydroLock™ Seams: 18° interlocking joints achieve IP68 protection - withstands 300km/h typhoons.

- Thermal Break Technology: Aerogel-infused edge spacers eliminate cold bridging (ΔT<0.5°C).

- Fire Safety: EN 13501-1 Class A2 certification without secondary fireproofing.

Installation Advantages

- SpeedClix™ System: No-tool click-lock assembly enables 55m²/hour installation.

- Precision Components: Laser-cut panels (±0.5mm tolerance) reduce waste by 30%.

- Adaptive Design: 1200/2400mm widths with curved section capability (5m radius).

Allowable span and heat transfer coefficient of PROPANEL polyurethane roof Sandwich panel(allowable deformation f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

30 |

0.32 |

9.32 |

L(m) |

2.60 |

2.30 |

2.08 |

1.91 |

1.72 |

|

50 |

0.31 |

10.15 |

L(m) |

3.59 |

3.17 |

2.85 |

2.61 |

2.33 |

|

75 |

0.21 |

11.18 |

L(m) |

4.64 |

4.07 |

3.66 |

3.34 |

2.96 |

|

100 |

0.19 |

12.22 |

L(m) |

5.57 |

4.88 |

4.38 |

3.99 |

3.53 |

|

120 |

0.16 |

13.05 |

L(m) |

6.28 |

5.49 |

4.92 |

4.48 |

3.97 |

|

150 |

0.11 |

14.30 |

L(m) |

7.30 |

6.39 |

5.73 |

5.22 |

4.62 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

3 Packing and Loading

Engineered packaging systems ensure perfect panel delivery worldwide through two customized approaches:

1. Palletized SmartPack™ (Ideal for Premium Protection)

- Heavy-Duty Pallets: ISPM15-certified timber or galvanized steel bases (1200×1000mm standard)

- Robotic Stacking: Precision-aligned bundles (max 2.5m height) with 8-way forklift access

- Damage Prevention: 3D corner protectors + moisture-resistant PE wrapping (200% tear strength)

- Labor Savings: 75% faster unloading with MHE equipment (1.5hrs/40HQ container)

2. Compact FlatPack™ (Maximized Container Utilization)

- Space Efficiency: 22% more panels per 40HQ vs palletized (up to 450m²)

- Interlock Technology: Non-slip EVA foam layers between panels

- Transit Security: High-tensile steel strapping (500kg break strength) + air cushion dunnage

Global Logistics Expertise

- Ocean Transport: CSC-certified containers with GPS-tracked humidity control (<60% RH)

- Road Safety: EN 12642 XL-standard load securing for overland haulage

- Quality Assurance: 5-point pre-shipment inspection (including flatness ≤3mm/m verification)

Our packaging solutions have delivered over 3 million m² of panels to 37 countries with zero transit damage claims since 2020. Choose Propanel for worry-free logistics tailored to your project scale and budget.

4 Project cases of PU Roofing Sandwich Panels

Project cases of PU Roofing Sandwich Panels--Mexico cold storage project 5000 square meters

5 RFQS of PU/PIR Roofing Sandwich Panels

1. What is the difference between PIR and PU sandwich panel?

Propanel's PIR panels offer 15% better thermal efficiency (0.02W/m·K) than PU, with higher fire resistance (Class B1 vs B2). PIR's closed-cell structure provides superior moisture resistance for cold storage applications.

---

2. What is the disadvantage of a PU sandwich panel?

Propanel PU panels have slightly lower heat resistance (max +110°C) than PIR. Requires additional fireproofing for certain industrial applications (upgrade to our FR-core option).

---

3. What is a PU sandwich panel?

Propanel PU panels feature polyurethane foam cores (0.024W/m·K) between steel/aluminum faces, ideal for warehouses and commercial buildings needing cost-effective insulation.

---

4. What is PIR sandwich panel?

Propanel PIR panels use polyisocyanurate cores with 180°C heat tolerance, perfect for food plants and pharmaceutical facilities requiring strict thermal/fire standards.

---

5. What is PU PIR?

Propanel's hybrid PU/PIR core combines affordability with enhanced fire performance (EN 13501-1 Class B), achieving 0.023W/m·K thermal conductivity for mid-range projects.

---

6. What is the purpose of a sandwich panel?

Propanel sandwich panels provide structural insulation for roofs/walls, reducing energy costs by 40% in industrial/commercial buildings while speeding up construction 3x.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on