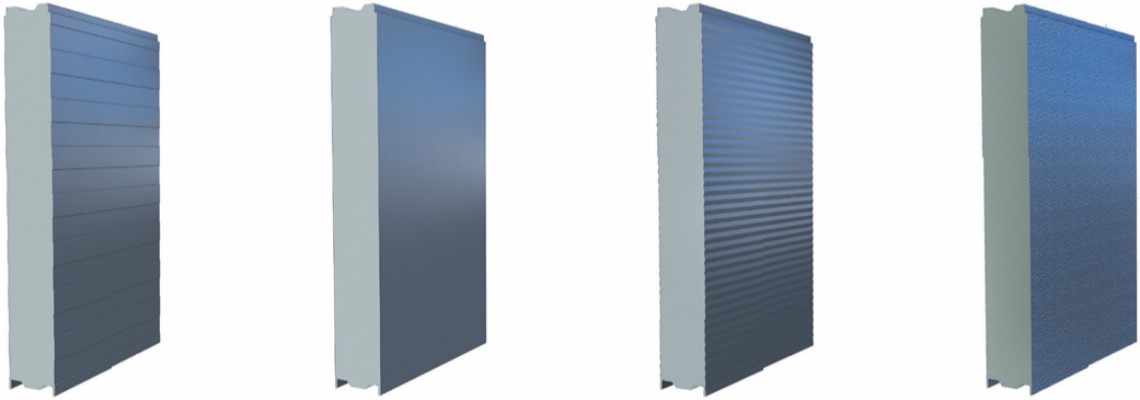

Polyurethane sandwich panel is the most suitable for cold storage. Extremely low thermal conductivity 0.021W/(m · K), excellent thermal insulation performance. The unique splicing design is used to bond with the high level steel plate, which leads to higher strength and stronger impact resistance. Fireproof and moisture-proof, convenient installation, diverse specifications and colors, stylish and beautiful.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

|

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Extreme heat preservation, temperature control and stability The thermal conductivity is extremely low (usually 0.021-0.025W/(m · K)) and the closed cell rate exceeds 95%, which can block the cold and heat exchange to the maximum extent and reduce the energy loss caused by temperature fluctuation in the cold storage. It is especially suitable for the wide temperature range cold storage of -50 ℃ to 10 ℃ and can maintain a stable low temperature environment for a long time.

Strong moisture-proof anti-seepage, adapt to high humidity The core material itself does not absorb water, and the panel (such as color steel plate, stainless steel plate) is more moisture-proof treatment, and the splice is sealed, which can effectively resist the condensation water generated by the temperature difference between the inside and outside of the cold storage, and avoid the heat preservation performance degradation or structural corrosion due to moisture.

Strong structure, low temperature impact resistance The core material and panel composite compressive strength is high (≥ 0.3MPa), not easy to embrittlement at low temperature, can withstand the impact of forklift and cargo in cold storage, and has strong wind and snow load resistance, suitable for long-term heavy load use.

Flame retardant fit cold storage safety By adding flame retardants, it can reach the B1 level flame retardant standard (some high-end products reach A level). When encountering fire, the burning speed is slow and the amount of smoke is small, which can delay the spread of fire and meet the fire safety requirements of flammable and explosive environments such as cold storage.

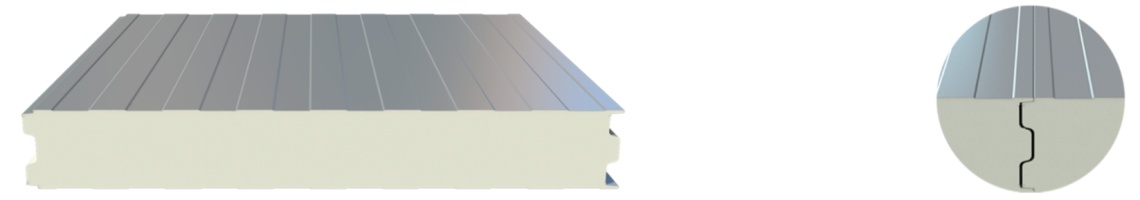

Efficient installation, good sealing performance Special splicing structures such as tongue-and-groove type and mortise-tenon joint type are adopted, and sealing rubber strips are matched. No additional thermal insulation materials are required during installation, which not only has a short construction period (more than 30% faster than the traditional thermal insulation method), but also can avoid cold leakage of splicing gaps and further improve thermal insulation efficiency.

Customized adaptation to diverse needs The thickness (50-250mm), panel material (color steel, stainless steel, aluminum foil) and length can be customized to meet the needs of different cold storage scales (such as small fresh-keeping storehouse, large-scale quick-frozen storehouse) and special environments (such as food grade and pharmaceutical grade clean requirements).

3 The Technical Specifications of Polyurethane Cold Room Panel

|

Thickness /mm |

Temperature difference between inside and outside/℃ |

Height of wall panel/m |

Length of roof panel/m |

Applicable cold storage temperature/℃ |

|

100 |

30 |

5 |

4.45 |

-15 |

|

125 |

35 |

5.5 |

5.2 |

-20 |

|

150 |

50 |

6 |

5.85 |

-25 |

|

175 |

65 |

6.5 |

6.3 |

-30 |

|

200 |

75 |

7 |

6.8 |

-40 |

The data shown in the left table are only available for the panel which subject to the internal-external pressure difference and contraction pressure, without wind load. If the specified length/height is exceeded or wind load occurs, panel supporters are required.

The above data are calculated according to the heat flow of 8~10W/m2.

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Polyurethane Cold Room Panel

·Fast frozen processing and refrigeration of food

·Food processing plant

·Storage of dairy products

·Biological products and medicines

·Indoor cold storge

·Cold storages for cold-chain transportation vehicle

6 Certification of Polyurethane Cold Room Panels

Propanel’s Cold room sandwich panel has successfully obtained international authoritative certifications such as CE, FM, and UL with its excellent quality. Certified by CE, it complies with the safety, health, and environmental protection standards of the European Union and can freely circulate in the European market. FM certification indicates outstanding performance in fire resistance and wind resistance, and can effectively cope with challenges in various industrial and commercial environments. UL certification further confirms that the product meets the standards in electrical safety, fire resistance, and material stability, meeting stringent requirements. These certifications are a testament to strength, highlighting the reliability and high quality of rock wool sandwich panels on a global scale. Whether in the field of building insulation or fire safety, it can provide customers with reliable protection.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on