75mm PU PIR Sandwich Panel for Cold Room offers superior thermal insulation and fire resistance. With a low thermal conductivity of 0.018-0.022 W/m·K, it ensures energy efficiency and maintains stable temperatures. FM-certified, it’s durable, waterproof, and ideal for cold storage facilities.

Item No :

PUWall0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

75mm PU PIR Sandwich Panel for Cold Room |

|

Density |

40~45kg/m³ |

|

Thickness |

40/50/60/75/80/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and roof |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B1 |

|

Thermal Conductivity |

≤0.023/≤0.02 |

|

Temperature Range |

40~43/40~50℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Thermal Insulation Excellence

The 75mm PU PIR Sandwich Panel for Cold Room delivers unmatched thermal insulation with a thermal conductivity of 0.019-0.022 W/m·K, ensuring energy efficiency in cold storage. Its 97% closed-cell PU/PIR core blocks water vapor, offering superior moisture resistance. FM-certified, it provides fire safety with a B1 rating, forming a protective coking layer to prevent flame spread. The prefabricated design speeds up installation, reducing costs. Ideal for refrigerated warehouses, these panels are hygienic, resisting bacteria, and use pentane-based technology for eco-friendly sustainability.

Fire Safety & Durability

Designed for cold storage, the 75mm PU PIR Sandwich Panel for Cold Room ensures fire safety with a B1 rating, outperforming EPS by forming a coking layer to halt flames. Its closed-cell structure resists moisture, ensuring durability for over 30 years. FM-certified, the panels feature corrosion-resistant metal facings and airtight technology to eliminate thermal bridges. Hygienic and bacteria-resistant, they’re perfect for food and pharmaceutical facilities. Quick to install, these panels offer a sustainable, high-performance solution.

Sustainable Efficiency

The 75mm PU PIR Sandwich Panel for Cold Room maximizes energy savings with a thermal conductivity of 0.019-0.022 W/m·K, reducing costs by 30%. Its pentane-based, non-fluorinated core aligns with global environmental standards. The 97% closed-cell design ensures moisture resistance, while FM certification guarantees fire safety. Prefabricated for fast installation, these hygienic panels suit cold chain logistics, offering durability and eco-friendly performance for sustainable cold storage solutions.

3 The Technical Specifications of PU PIR Sandwich Panel for Cold Room

|

Thickness /mm |

Temperature difference between inside and outside/℃ |

Height of wall panel/m |

Length of roof panel/m |

Applicable cold storage temperature/℃ |

|

100 |

30 |

5 |

4.45 |

-15 |

|

125 |

35 |

5.5 |

5.2 |

-20 |

|

150 |

50 |

6 |

5.85 |

-25 |

|

175 |

65 |

6.5 |

6.3 |

-30 |

|

200 |

75 |

7 |

6.8 |

-40 |

Optimized Thermal PerformanceThe 75mm PU PIR Sandwich Panel for Cold Room is engineered for superior thermal insulation, boasting a thermal conductivity of 0.019-0.022 W/m·K. Designed for a 25°C temperature differential, it maintains stable -10°C conditions, ideal for chilled storage. With a 97% closed-cell PU/PIR core, it ensures moisture resistance and minimizes heat flow (8-10 W/m²). FM-certified, these panels support wall heights up to 4.5 meters and roof spans of 4 meters, delivering energy efficiency for cold chain facilities.

Durability and Fire SafetyBuilt for resilience, the 75mm PU PIR Sandwich Panel for Cold Room withstands internal-external pressure shifts and contraction stresses. Its B1 fire-rated core forms a protective coking layer, enhancing fire safety over EPS panels. Corrosion-resistant metal facings ensure durability for over 30 years, while the airtight design prevents cold steam bridges. Hygienic and bacteria-resistant, these panels are perfect for food and pharmaceutical storage, offering reliable performance in demanding environments.

Efficient Installation and SustainabilityThe 75mm PU PIR Sandwich Panel for Cold Room features a prefabricated design for rapid, cost-effective installation, reducing labor expenses. Its pentane-based, non-fluorinated core aligns with environmental standards, promoting sustainability. Supporting moderate wind loads with additional reinforcements, these panels ensure structural stability. Ideal for cold storage, they offer energy savings and long-term reliability, making them a top choice for eco-friendly, high-performance cold chain solutions.

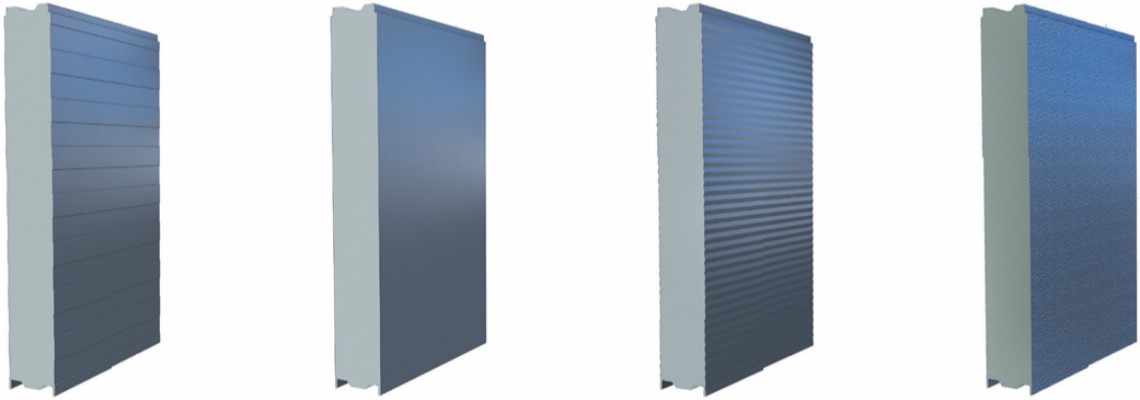

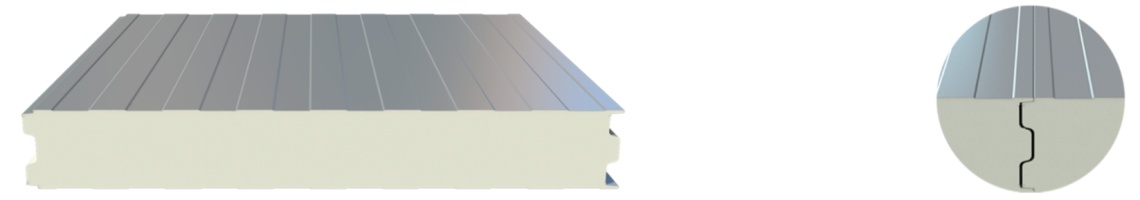

4 Plate Type and Node Figure

Cold storage board plug-in interface-C type

Cold storage board plug-in interface-E type

5 Application Areas of Cold Storage Panels

Food and Dairy Storage ExcellenceThe 75mm PU PIR Sandwich Panel for Cold Room is a game-changer for food storage and dairy processing, ensuring optimal temperature control. With a thermal conductivity of 0.019-0.022 W/m·K and a 97% closed-cell PU/PIR core, it delivers superior insulation, preserving the freshness of perishable goods like milk and produce. FM-certified, these panels offer fire safety with a B1 rating, ideal for refrigeration facilities. Their hygienic, bacteria-resistant surfaces meet stringent food safety standards, while the prefabricated design ensures quick installation, reducing costs. Perfect for cold storage warehouses, they support energy efficiency and sustainability.

Pharmaceutical and Cold Chain LogisticsThe 75mm PU PIR Sandwich Panel for Cold Room excels in pharmaceutical storage and cold chain logistics, maintaining precise temperatures for medicines and biologics. Its moisture-resistant, closed-cell structure prevents vapor infiltration, ensuring product integrity. FM-certified for fire resistance, it enhances safety in sensitive environments. The panels’ pentane-based, eco-friendly core aligns with sustainable practices, cutting energy costs by up to 30%. Used in cold storage transport and distribution hubs, they ensure seamless temperature regulation. Durable and easy to install, these panels are the top choice for reliable, high-performance cold chain solutions.

6 FAQS of PU/PIR Cold Room Sandwich Panels

1. What are cold room panels called?

PU PIR Sandwich Panel for Cold Room is an insulated panel for temperature-controlled spaces. It offers superior thermal insulation (0.019-0.022 W/m·K), moisture resistance, and fire safety. FM-certified, it’s ideal for cold storage and pharmaceutical use, ensuring energy efficiency and hygienic conditions.

2. What is a sandwich wall panel called?

The 75mm PU PIR Sandwich Panel for Cold Room is a sandwich wall panel with a PU/PIR core between metal facings. It ensures thermal insulation, fire resistance (B1 rating), and strength, perfect for cold storage and commercial buildings with energy-efficient, durable designs.

3. What materials are used in cold room panels?

The 75mm PU PIR Sandwich Panel for Cold Room uses a PU/PIR foam core encased in durable metal skins. This delivers thermal insulation, moisture resistance, and fire safety, making it ideal for cold storage and food processing with hygienic, long-lasting performance.

4. What are the specifications of cold room panels?

The 75mm PU PIR Sandwich Panel for Cold Room has a thermal conductivity of 0.019-0.022 W/m·K and a 97% closed-cell structure. FM-certified, it ensures energy efficiency, moisture resistance, and stable temperatures for cold storage, available in 50-200mm thicknesses.

5. What equipment supports cold room panels?

The 75mm PU PIR Sandwich Panel for Cold Room enhances refrigeration units and evaporators with its airtight, insulated design. FM-certified, it optimizes energy efficiency and ensures consistent cooling for perishables in cold storage, supporting seamless, reliable cold chain operations.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on