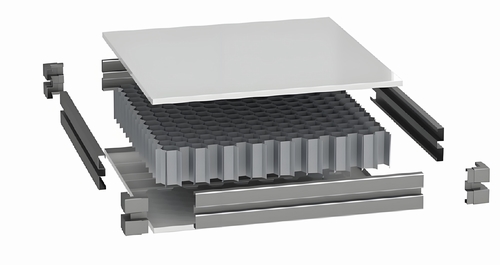

The Rock Wool Handmade Clean Room Sandwich Panel ensures superior fire resistance, thermal insulation, and hygienic conditions. Crafted with a rock wool core, it offers durability and soundproofing, ideal for pharmaceutical and food clean rooms, meeting strict safety standards.

Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Type |

Rock Wool Handmade Clean Room Sandwich Panel |

|

Wall Thickness |

100mm |

|

Standard Module |

980mm, 1160mm, 1180mm, 1200mm, non-standard can be customized |

|

Diagonal Error |

≤1mm |

|

Maximum Length |

≤10000mm |

|

Panel Material |

PE polyester, PVDF (fluorocarbon), salt plate, antistatic, static conductive, stainless steel, HDP (high durability polyester) |

|

Panel Thickness |

0.426mm, 0.45mm, 0.476mm, 0.5mm, 0.6mm, 1.0mm |

|

Filling Core Material |

Rock wool (bulk density 100K, ≥120K and above can be customized) + double-layer 10mm glass magnesium board |

|

Galvanized Frame |

1.0mm |

|

Corner Pieces |

1.0mm galvanized angle fittings |

|

Protective Film |

0.06mm thick, >0.06mm and above can be customized |

|

Connection |

Center aluminum connection |

Superior Material Quality

The Rock Wool Handmade Clean Room Sandwich Panel features stainless steel or anti-static aluminum surfaces, preventing particle contamination. Its rock wool core (50-100mm) ensures A1 fire resistance and thermal insulation. Antimicrobial coatings meet GMP standards, ideal for pharmaceutical and food cleanrooms.

Precision and Performance

Designed for ISO 5-8 cleanrooms, the Rock Wool Handmade Clean Room Sandwich Panel offers airtight installation with ±0.5mm precision. The rock wool core provides soundployment and stability, perfect for labs and operating theaters, ensuring contamination-free, energy-efficient environments.

Versatile and Sustainable

The Rock Wool Handmade Clean Room Sandwich Panel supports biomedical and pharmaceutical applications with ESD-compliant surfaces and recyclable materials. Custom-fabricated for modularity, it ensures fire safety and thermal efficiency, a top choice for eco-friendly, high-performance cleanroom solutions.

Seamless and Hygienic Design

The Rock Wool Handmade Clean Room Sandwich Panel features seamless corner fabrication for airtight integration, eliminating leakage points. Its hygienic, wipe-clean surfaces resist microbes and withstand disinfectants, reducing cleaning time by 70%. Ideal for pharmaceutical and food processing cleanrooms, ensuring GMP compliance.

Thermal and Fire Performance

With a rock wool core, the Rock Wool Handmade Clean Room Sandwich Panel delivers thermal insulation (≤0.043 W/m·K) and A1 fire rating (EI120). Its consistent R-value minimizes thermal bridging, saving up to 15% energy. Perfect for semiconductor and hospital cleanrooms requiring stable, safe environments.

Precision and Versatility

Crafted with ±0.5mm precision, the Rock Wool Handmade Clean Room Sandwich Panel ensures modular installation efficiency. Available in 304 stainless steel or coated aluminum, it supports ISO 5-8 cleanrooms and biomedical labs. Its eco-friendly core enhances sustainability and performance in sterile applications.

4 Installation of Handmade Clean Room Sandwich Panel

Precision Installation

The Rock Wool Handmade Clean Room Sandwich Panel ensures ISO 5 cleanroom compliance with laser-guided, ±0.5mm precision installation. Using 3D site scanning, our certified teams achieve flawless alignment, ideal for pharmaceutical and semiconductor facilities, ensuring hygienic, high-performance sterile environments with rapid setup.

Structural Excellence

Featuring a rock wool core, the Rock Wool Handmade Clean Room Sandwich Panel offers A1 fire resistance and thermal insulation. Robust aluminum framing and anti-vibration anchors ensure structural stability, perfect for biomedical labs and hospital theaters, exceeding EN 14575 standards for seamless, durable construction.

Airtight and Hygienic

The Rock Wool Handmade Clean Room Sandwich Panel uses an airtight gasket system tested to 35Pa, paired with zero-gap corner fusion. FDA-approved sealants create a microbial barrier, ensuring hygienic conditions for food processing and pharmaceutical cleanrooms, with minimal particulate emission.

Validated Performance

With surface flatness of ≤1mm/2m and particulate emission below 3 particles/ft³ (≥0.5μm), the Rock Wool Handmade Clean Room Sandwich Panel guarantees energy efficiency and sustainability. Post-installation testing ensures ISO 14644 compliance, reducing certification time by 40% for reliable cleanroom solutions.

5 Project cases of Handmade Clean Room Sandwich Panel

Project cases of Handmade Clean Room Sandwich Panel--Malaysia Electronics Factory 10000 square meters 2019

Project cases of Handmade Clean Room Sandwich Panel--Vaccine plant in Russia 8000 square meters 2021

6 FAQS of Handmade Clean Room Sandwich Panel

1. What are clean room panels made of?

Propanel cleanroom panels feature medical-grade stainless steel or powder-coated aluminum surfaces with PIR/rock wool cores. Our antimicrobial finishes meet ISO 14644 standards for pharmaceutical and electronic manufacturing environments.

---

2. What is a sandwich panel called?

Professionally termed "Composite Insulated Panels", Propanel's versions integrate fireproof cores with durable cladding for industrial partitions and cold storage walls.

---

3. What are the benefits of sandwich panels?

Propanel's sandwich panels deliver 60% faster installation, 30% energy savings, and A1 fire ratings. Their lightweight yet robust design suits warehouses, cleanrooms, and food processing plants.

---

4. What are three different types of core used in sandwich panels?

Propanel offers PIR (best insulation), rock wool (fireproof), and aluminum honeycomb (ultra-light) cores. Each undergoes 12 quality checks for consistent performance.

---

5. Are sandwich panels strong?

Propanel's steel-faced sandwich panels withstand 150km/h winds and 1.5kN/m² loads. Reinforced joints ensure structural integrity for decades in harsh environments.

---

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on