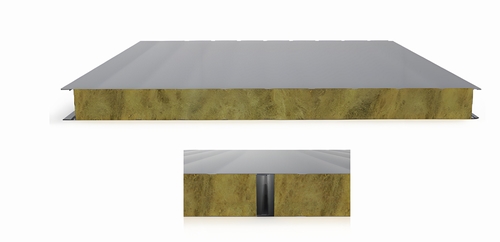

The Mechanized Rock Wool Clean Room Sandwich Panel offers exceptional fire resistance, thermal insulation, and hygienic performance. Its rock wool core ensures durability and soundproofing, ideal for pharmaceutical and semiconductor cleanrooms, meeting stringent ISO standards with precision manufacturing.

Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Mechanized Rock wool Clean Room Sandwich Panel |

|

Core Material |

Rockwool,EPS,honeycomb,glass magnesium etc. |

|

Panel Thickness |

50/75/100/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/1150/980/1180mm |

|

Skin material |

PPGI, Pre-painted aluminum plate, SS Steel, Ti-Zn Steel etc. |

|

Pre-painted |

PE/HDP/PVDF |

|

Fireproof Grade |

A |

|

Length |

Customized. |

|

Customized design is welcomed. |

|

Superior Thermal Insulation

The Mechanized Rock Wool Clean Room Sandwich Panel ensures excellent thermal insulation with a low-conductivity rock wool core (≤0.043 W/m·K). It minimizes heat loss, stabilizes indoor temperatures, and boosts energy efficiency, ideal for pharmaceutical and semiconductor cleanrooms requiring precise climate control.

Hygienic and Clean Design

Featuring high-flatness metal sheets and seamless splicing, the Mechanized Rock Wool Clean Room Sandwich Panel prevents dust and pollutant entry. Its hygienic surfaces meet strict ISO cleanroom standards, ensuring a contamination-free environment for sensitive applications like food processing and medical labs.

Robust Strength and Stability

Produced on automated lines, the Mechanized Rock Wool Clean Room Sandwich Panel offers high dimensional accuracy. Its metal panels bond tightly with the rock wool core, resisting pressure and impact. This ensures durability and stability for demanding cleanroom environments without deformation.

Durable and Aesthetic Appeal

The Mechanized Rock Wool Clean Room Sandwich Panel features corrosion-resistant metal surfaces for long-lasting performance. With vibrant, uniform colors and customizable styles, it enhances aesthetic appeal while offering wear resistance, ideal for modern cleanroom designs with minimal maintenance.

The Mechanized Rock Wool Clean Room Sandwich Panel features a tongue-and-groove system for fast, secure installation. Precision-aligned panels interlock tightly, ensuring airtightness and a gap-free surface. Ideal for pharmaceutical and semiconductor cleanrooms, it maintains ISO standards with durable, hygienic performance.

Thermal and Fire Efficiency

With a rock wool core, the Mechanized Rock Wool Clean Room Sandwich Panel offers A1 fire resistance and thermal insulation (≤0.043 W/m·K). Its sturdy, corrosion-resistant design ensures long-term stability, supporting energy efficiency and safety in demanding cleanroom environments like medical labs.

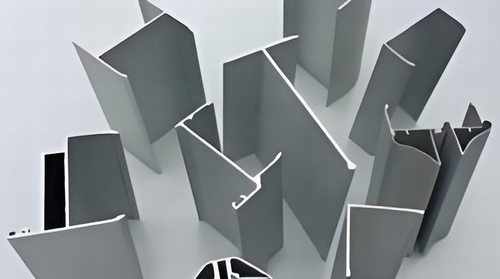

4 Clean Room Aluminum Profile Accessories

Precision and Cleanliness

The Mechanized Rock Wool Clean Room Sandwich Panel ensures contamination-free environments with seamless modular design. Its rock wool core and high-precision aluminum profiles meet ISO cleanroom standards, ideal for pharmaceutical and electronics industries. Easy to clean, it minimizes particle risks, ensuring hygienic reliability.

Durability and Efficiency

Featuring corrosion-resistant surfaces and a robust rock wool core, the Mechanized Rock Wool Clean Room Sandwich Panel offers A1 fire resistance and thermal insulation. Its lightweight, strong structure supports quick assembly, enhancing energy efficiency and longevity in biotech and cleanroom applications.

5 Project cases of Mechanized Clean Room Sandwich Panel

Project cases of Mechanized Clean Room Sandwich Panel--Dubai Food Processing Factory 5000 square meters 2017

Project cases of Mechanized Clean Room Sandwich Panel--Singapore Laboratory 1000 square meters 2012

6 FAQ of Mechanized Clean Room Sandwich Panel

1.What type of panel is used in clean rooms?

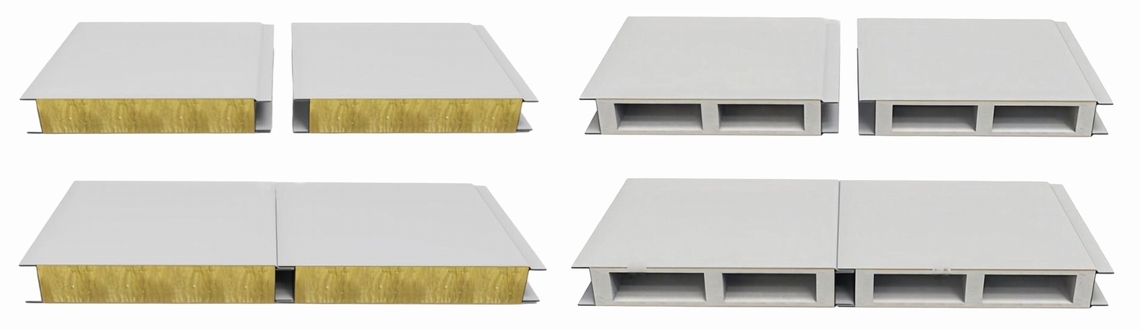

There are generally mechanically made clean panels and hand-made clean panels.

2. What are the core materials of the clean room panel?

The core materials of clean panels include polystyrene, extruded polystyrene, polyurethane, rock wool, glass wool, aluminum honeycomb, paper honeycomb, glass magnesium board, etc. Each has different performance characteristics such as thermal insulation, fire resistance, and strength, and is suitable for different clean places.

3.What is the difference between hand-made clean panels and mechanically-made clean panels?

The hand-made clean panels production process is complex, flexible size customization, rich plate type, fine appearance, high strength, better fire performance, but the price is expensive. The mechanically made clean panels is produced by the machine, with high efficiency, relatively fixed size, single plate type, slightly poor strength, relatively rough appearance, and low price, but the specific performance is also different due to core materials and other factors.

4. How to fix a sandwich panel on a wall?

Here's how to fix a sandwich panel on a wall. Firstly, clean the wall surface and prepare tools like drills and screws. Then, install a steel or wooden framework on the wall evenly and firmly. Next, cut the sandwich panel to the right size and place it on the framework. Fix it with screws, making sure the screws are evenly spaced. Finally, seal the joints between the panels with sealant to prevent leakage. Check the installation to ensure the panel is secure and flat.

5. What is the standard length of a sandwich panel?

The length of the general sandwich board is between 2 meters and 16 meters, if it is for overseas customers to better load the cabinet, the general length is less than 11.9 meters.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on