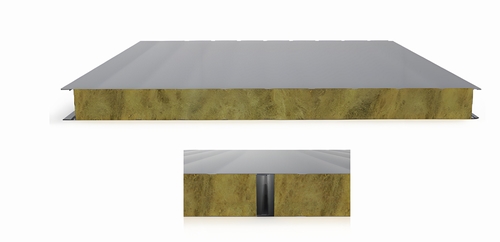

The Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel offers superior fire resistance, thermal insulation, and hygienic properties. With a rock wool core and glass magnesium boards, it ensures durability and moisture resistance, ideal for clean rooms in pharmaceutical and food industries.

Item No :

HANDCLEAN0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

40 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel |

|

Core Material |

Rockwool,EPS,honeycomb,glass magnesium etc. |

|

Panel Thickness |

50/75/100/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/1150/980/1180mm |

|

Skin material |

PPGI, Pre-painted aluminum plate, SS Steel, Ti-Zn Steel etc. |

|

Pre-painted |

PE/HDP/PVDF |

|

Fireproof Grade |

A |

|

Length |

Customized. |

|

Customized design is welcomed. |

|

Superior Fire and Thermal Performance

The Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel excels in fire resistance with a rock wool core, achieving a Class A rating for unmatched safety in clean room environments. Its thermal insulation (conductivity ≤0.043 W/m·K) ensures energy efficiency, maintaining stable temperatures in pharmaceutical and food processing facilities. The hygienic design resists bacteria, meeting stringent clean room standards.

Durability and Moisture Resistance

Crafted with glass magnesium boards and a robust rock wool core, this panel offers exceptional durability and moisture resistance, preventing water seepage in high-humidity settings. Its corrosion-resistant properties ensure a lifespan exceeding 30 years, ideal for demanding clean room applications. The lightweight yet strong structure supports rapid, cost-effective installation, reducing project timelines while maintaining structural integrity.

Eco-Friendly and Versatile Design

The Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel uses eco-friendly, recyclable materials, aligning with sustainable construction goals. Its sleek, customizable finishes enhance aesthetics in clean rooms, laboratories, and medical facilities. Prefabricated for precision, it ensures seamless integration and soundproofing, making it a top choice for professionals seeking reliable, high-performance, and environmentally conscious clean room solutions.

Advanced Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel Technology

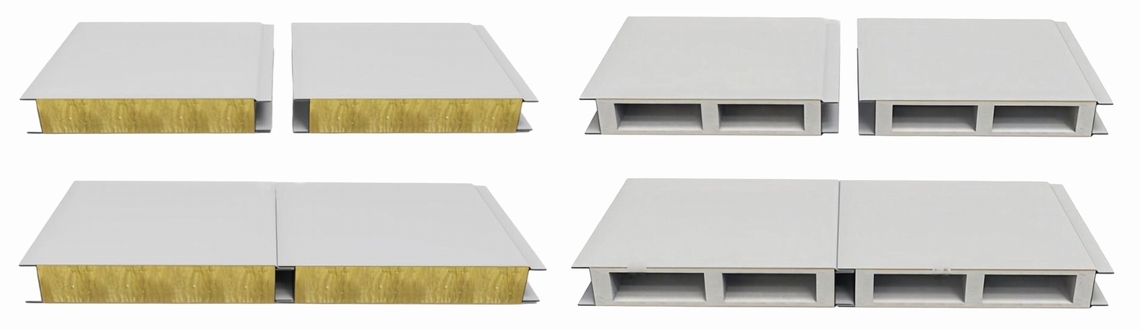

Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panels represent cutting-edge construction solutions for pharmaceutical, electronics, and biotechnology facilities. These innovative panels combine fire-resistant glass magnesium boards with high-density rock wool insulation core, delivering superior thermal performance and acoustic control. The mechanism design enables rapid assembly while maintaining strict contamination control standards required in ISO-certified environments.

Superior Performance and Environmental Benefits

The glass magnesium facing provides exceptional moisture resistance and antimicrobial properties, preventing bacterial growth and ensuring long-term hygiene compliance. Rock wool insulation offers outstanding fire safety ratings and sound dampening capabilities, making these panels ideal for sensitive manufacturing processes. The mechanized installation system reduces construction time by 40% compared to traditional methods, minimizing disruption to operational facilities while maintaining precise dimensional accuracy.

Professional Installation and Quality Assurance

Each Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panel undergoes rigorous quality testing to meet international cleanroom standards. The integrated locking mechanism ensures airtight seals between panels, eliminating thermal bridges and maintaining consistent indoor climate control. These panels support various ceiling heights and can accommodate specialized equipment installations, providing flexible solutions for modern cleanroom applications across multiple industries.

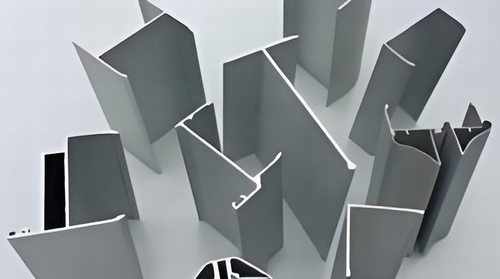

4 Clean Room Aluminum Profile Accessories

Versatile Installation Systems and Technical Specifications

The modular Clean Room Aluminum Profile Accessories system enables flexible configuration for walls, ceilings, and equipment mounting frameworks. Anti-static properties eliminate particle attraction, while smooth finishes prevent bacterial adhesion and simplify cleaning procedures. Each profile incorporates integrated gasket channels and connection points, supporting various panel thicknesses and ensuring airtight seals throughout the installation process.

Cost-Effective Solutions for Critical Applications

These aluminum profile accessories deliver exceptional value through reduced maintenance requirements and extended service life in demanding cleanroom conditions. The lightweight design minimizes structural load while maintaining superior strength-to-weight ratios essential for multi-story installations. Compatible with standard cleanroom panels and filtration systems, these accessories streamline construction timelines and reduce total project costs for pharmaceutical and biotechnology facilities.

5 Project cases of Mechanized Clean Room Sandwich Panel

Project cases of Mechanized Clean Room Sandwich Panel--Dubai Food Processing Factory 5000 square meters 2017

Project cases of Mechanized Clean Room Sandwich Panel--Singapore Laboratory 1000 square meters 2012

6 FAQ of Mechanized Clean Room Sandwich Panel

1. Which Glass Magnesium Rock Wool Panel Types Are Available for Pharmaceutical Facilities?

Glass Magnesium Rock Wool Mechanism Clean Room Sandwich Panels feature automated production technology and custom fabrication options. Machine-manufactured panels offer consistent quality, cost-effectiveness, and rapid delivery schedules. Hand-crafted variants provide specialized dimensions, enhanced fire ratings, and premium finishes for critical pharmaceutical applications requiring superior contamination control.

2. What Rock Wool Core Specifications Define Glass Magnesium Sandwich Panel Performance?

Premium glass magnesium boards combined with high-density rock wool cores deliver exceptional thermal insulation, fire resistance Class A ratings, and superior structural integrity. These advanced core materials provide excellent sound dampening, moisture resistance, and long-term dimensional stability essential for ISO-certified cleanroom environments in biotechnology and electronics manufacturing.

3. How Do Mechanized Glass Magnesium Rock Wool Panels Compare to Traditional Options?

Mechanized Glass Magnesium Rock Wool panels offer streamlined production, standardized dimensions, and competitive pricing while maintaining excellent performance characteristics. Unlike conventional alternatives, these panels feature consistent quality control, reduced lead times, and optimized material utilization, making them ideal for large-scale cleanroom construction projects.

4. What Installation Methods Apply to Glass Magnesium Rock Wool Sandwich Panels?

Professional installation requires prepared substrate surfaces, precision-engineered support frameworks, and specialized fastening systems. Glass Magnesium Rock Wool panels mount securely using concealed fixings, ensuring seamless joints and airtight seals. Proper installation techniques guarantee optimal performance, structural integrity, and compliance with cleanroom industry standards.

5. What Are Standard Glass Magnesium Rock Wool Panel Dimensions and Shipping Requirements?

Standard Glass Magnesium Rock Wool Mechanism panels range from 2-16 meters length, with export specifications optimized for container shipping below 11.9 meters. Custom dimensions accommodate specific project requirements while maintaining structural performance. Efficient packaging ensures damage-free international delivery for global cleanroom construction projects.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on