Most popular choice of energy efficient building materials. Excellent thermal insulation with a thermal conductivity of 0.024-0.041 W/m·K, reducing energy consumption. Light weight yet sturdy, simplify handle and install. Cost reducing, durability, closed-cell structure offers water resistance,can be customized to fit various architectural requirements.

Item No :

EPSWALL0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

18 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Expandable Polystyrene Sandwich Wall Panel |

|

Thickness |

50/75/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/980mm |

|

Density |

8/10/12/14/16/18/20kg/m³ |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B2 |

|

Thermal Conductivity |

0.042 |

|

Temperature Range |

-40~90℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Thermal insulation: Low thermal conductivity, about 0.024-0.041W/ (m · K), effectively reducing heat transfer and keeping indoor temperature stable.

High cost performance: Low raw material cost, low transportation cost and installation cost.

Light weight: About 10kg/㎡, much lower than traditional roofing materials, reduce the overall

weight of the building, reduce the cost of foundation and structure.

Easy installation: Using plug-in or splicing installation methods, fast construction speed, greatly shorten the construction period. Cut at will, easy to install and adjust on site.

High strength: With high-strength steel plate as the panel, and EPS core composite, has good bending and compressive performance, withstand a certain roof load.

Fireproof performance: surface and core materials can be made of non-combustible or non-combustible materials, which can meet certain fire protection requirements, and the oxygen index can generally reach 32.0 and above.

Allowable vertical load and heat transfer coefficient of PROPANEL EPS sandwich roof panel (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/㎡·k) |

Weight |

Load P=KN/m2 |

0.6 |

0.8 |

1 |

1.2 |

1.5 |

|

50 |

0.64 |

10 |

L(m) |

6.5 |

5.8 |

5.1 |

4.6 |

4 |

|

75 |

0.43 |

10.45 |

L(m) |

7.8 |

7 |

6.2 |

5.6 |

5 |

|

100 |

0.32 |

10.9 |

L(m) |

9.5 |

8.5 |

7.5 |

6.8 |

6 |

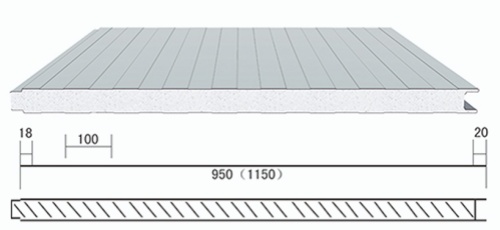

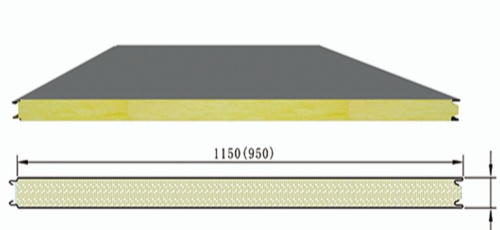

3 Joint Type for EPS Sandwich Wall Panels

There are 2 kinds of lap type for EPS Wall sandwich panel: one is cap type, another is overlap type.

Pictures are as below:

Socket Type 950 1150 Wall Panel

S-Socket Type 950 1150 Wall Panel

4 Application of EPS Wall Sandwich Panel

EPS core panels have excellent performance and are widely used in the construction industry and temporary buildings. In the field of construction: for residential buildings, EPS core panels can effectively enhance the insulation and heat preservation performance of the houses, reduce energy consumption, and their good sound insulation effect can create a quiet and comfortable living space for residents. For industrial plants and warehouses, EPS core panels are used as wall and roof materials, which can meet the requirements of insulation and moisture prevention, protect internal equipment and goods, and due to their lightweight characteristics, they are easy to install and can shorten the construction period.

In temporary buildings, such as temporary dormitories at construction sites and disaster relief resettlement houses, EPS core panels can be quickly erected due to their convenient installation and low cost, and can promptly meet the temporary living needs. In agricultural facilities, such as greenhouse sheds, EPS core panels are used, which can maintain a stable temperature inside the shed, create a suitable environment for crop growth, and its waterproof property can also reduce the damage to the shed structure caused by moisture.

5 Project cases of EPS Sandwich Wall Panel

Project cases of EPS Sandwich Wall Panel--Brazilian logistics warehouse

Project cases of EPS Sandwich Roof Panel--Japanese electronic equipment factory

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on