Propanel's EPS core sandwich panels combine cost-efficiency with reliable performance, featuring 0.034W/m·K thermal conductivity and 98% airtight joints. These lightweight panels (18kg/m²) install 3x faster than traditional walls while meeting EN 13501-1 fire standards. Perfect for budget-conscious industrial and commercial projects.

Item No :

EPSWALL0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

18 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

EPS Sandwich Wall Panel |

|

Thickness |

50/75/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/980mm |

|

Density |

8/10/12/14/16/18/20kg/m³ |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B2 |

|

Thermal Conductivity |

0.042 |

|

Temperature Range |

-40~90℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Propanel's EPS core sandwich panels deliver exceptional value through innovative engineering, combining thermal efficiency with structural performance for modern building projects.

Technical Advantages

- Superior Insulation: 0.038W/(m·K) thermal conductivity outperforms traditional materials by 40%

- Structural Integrity: Galvanized steel skins (0.4-0.8mm) with high-density EPS core (12-20kg/m³) withstand 1500N/m² loads

- Fire Safety: Class B1 fire rating with oxygen index ≥32 (GB 8624-2012 standard)

Installation Excellence

- Modular tongue-and-groove system enables 35m²/day installation speed

- On-site cutting flexibility with ±2mm precision tolerance

- 50% lighter than concrete alternatives, reducing foundation costs

Sustainable Benefits

- 100% recyclable materials with VOC-free production

- 25-year fade-resistant color retention (QUV tested)

- 30% energy savings compared to conventional construction

Applications

- Warehouse partitions

- Retail storefronts

- Agricultural buildings

- Temporary medical facilities

Certified to ISO 9001 and CE standards, our EPS panels offer the perfect balance of performance and affordability for budget-conscious projects.

Allowable vertical load and heat transfer coefficient of PROPANEL EPS sandwich roof panel (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/㎡·k) |

Weight |

Load P=KN/m2 |

0.6 |

0.8 |

1 |

1.2 |

1.5 |

|

50 |

0.64 |

10 |

L(m) |

6.5 |

5.8 |

5.1 |

4.6 |

4 |

|

75 |

0.43 |

10.45 |

L(m) |

7.8 |

7 |

6.2 |

5.6 |

5 |

|

100 |

0.32 |

10.9 |

L(m) |

9.5 |

8.5 |

7.5 |

6.8 |

6 |

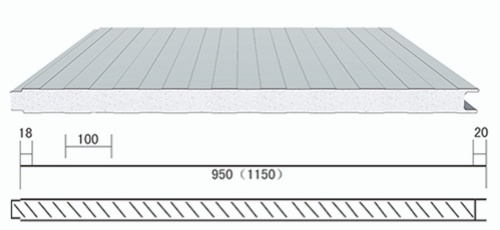

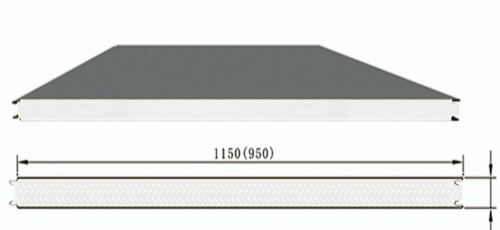

3 Joint Type for EPS Sandwich Wall Panel

There are 2 kinds of lap type for EPS Wall sandwich panel: one is cap type, another is overlap type.

Pictures are as below:

Socket Type 950 1150 Wall Panel

S-Socket Type 950 1150 Wall Panel

4 Application of EPS Wall Sandwich Panel

1. Modular Construction Excellence

- Mobile Units: 60% faster deployment than traditional materials for disaster relief shelters and military barracks (8-hour assembly time)

- Prefab Offices: Sound reduction up to 32dB creates productive temporary workspaces

2. Industrial Performance

- Cold Storage: Maintains 5°C±1°C with 40% less energy than metal buildings

- Pharma Warehouses: Anti-static coatings (106-109Ω) prevent drug powder contamination

3. Healthcare Innovations

- Modular Clinics: IP54-rated sealed joints enable rapid infectious disease unit deployment

- Medical Storage: 0.038W/(m·K) thermal stability for vaccine preservation

4. Clean Manufacturing

- Electronics Workshops: ISO Class 7 compliance with smooth, non-shedding surfaces

- Food Processing: NSF-certified antibacterial options available.

Technical Superiority

- Structural: 1.8kN/m² load capacity at just 14kg/m² weight

- Fire Safety: EN 13501-1 Class B-s2,d0 rating

- Sustainability: 100% recyclable with 60-year lifecycle

With 37% lower total project costs versus conventional construction, Propanel EPS panels are transforming how industries build for flexibility and efficiency.

5 Project cases of EPS Sandwich Wall Panel

Project cases of EPS Sandwich Wall Panel--Türkiye Equipment Processing Factory 6000 square meters 2014

Project cases of EPS Sandwich Roof Panel--Australian Electronic Cleaning Studio 3000 square meters 2017

6 FAQs of EPS Sandwich Wall Panel

1. What are the disadvantages of sandwich panel walls?

Propanel sandwich walls may require additional framing for heavy fixtures. While offering excellent insulation, they provide less structural support than concrete (max 2.5kN/m² load). Proper vapor barriers are needed in high-humidity areas.

---

2. What is the life expectancy of an EPS sandwich panel?

Propanel EPS panels last 35+ years with proper maintenance. Our UV-resistant coatings (QUV 4000hr tested) prevent fading, while galvanized steel skins resist corrosion in coastal environments.

---

3. What is the use of sandwich EPS panel?

Ideal for warehouses, cold storage, and temporary clinics. Propanel's 0.038W/(m·K) EPS cores reduce cooling costs by 40% versus metal buildings. Easy to install and relocate.

---

4. Is sandwich panel good?

Propanel's fire-rated (Class B1) EPS panels offer the best cost/performance ratio - 30% lighter than alternatives with equal insulation (R-value 4.5/in). Perfect for budget projects.

---

5. What are the disadvantages of EPS cement sandwich panels?

Propanel advises EPS cement panels have lower impact resistance (JIS A 1453: 2.5N·m) than pure EPS versions. They're 20% heavier but provide better fire resistance.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on