The top choice for energy-saving building materials. Excellent insulation and heat insulation properties, with a thermal conductivity of 0.024 - 0.041 W/m·K, which can reduce energy consumption. Lightweight yet highly supportive, easy to install quickly. Low cost, high durability, and also has waterproof and fireproof properties. It can be customized according to various building needs.

Item No :

EPSWALL0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

18 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

Expandable Polystyrene Sandwich Wall Panel |

|

Thickness |

50/75/100/120/150/200mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

950/980mm |

|

Density |

8/10/12/14/16/18/20kg/m³ |

|

Skin material |

PPGL,PPGI,Stainless steel,aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

B2 |

|

Thermal Conductivity |

0.042 |

|

Temperature Range |

-40~90℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Excellent thermal insulation and heat preservation properties, reducing energy consumption costs

The thermal conductivity of EPS core material is extremely low (usually ≤ 0.041 W/(m·K)), far superior to that of traditional brick walls (thermal conductivity is approximately 0.81 W/(m·K)). It can effectively block the transfer of heat between indoors and outdoors, achieving energy conservation and environmental protection, and aligning with the concept of green and energy-efficient buildings.

Lightweight and high strength, reducing structural load

The density of EPS core material is only 8-28 kg/m³. When combined with metal panels, the overall weight of the panel is much lighter than brick walls of the same thickness (brick wall weight is approximately 190 kg/m³). This lightweight material can not only reduce the construction cost of the foundation but also avoid safety hazards caused by excessive structural weight. At the same time, the outer layer of the color steel plate has certain strength, with strong resistance to impact and deformation, capable of withstanding minor collisions during daily use, ensuring the long-term stability of the wall.

Outstanding sound insulation effect, enhancing space comfort

The internal structure of EPS core material is a closed honeycomb structure, which can effectively absorb sound waves and reduce noise transmission. The air sound insulation of ordinary EPS wall panels can reach over 40 dB. If double-layer core material or special surface layer design is adopted, the sound insulation can be increased to over 45 dB.

Fire resistance meets standards, ensuring usage safety

By adding flame retardants, EPS wall panels can reach B1 level. At the same time, EPS core material does not produce toxic gases when heated and has less smoke when burning, allowing for more time for personnel evacuation and further improving the safety coefficient of the building.

Convenient and efficient construction, shortening construction period

EPS wall panels are mostly factory-precast standardized components, and the side edges are designed with tongue-and-groove or mortise-and-tenon connection structures. On-site construction only requires splicing and fixing with bolts and connecting parts, reducing the construction period by over 60%. In addition, the panel is lightweight, and no large lifting equipment is required. Manual transportation and installation are possible, effectively reducing construction costs and time costs.

Strong weather resistance, reducing later maintenance

EPS core material has good chemical stability and is not easily eroded by environmental factors such as humidity, high temperature, and acid-base. It is unlikely to have problems such as mold, corrosion, or cracking over a long period of use. The outer layer of the color steel plate is usually treated with galvanization or spray painting, having excellent anti-corrosion ability, with a lifespan of 15-20 years in outdoor environments. After installation of the EPS wall panel, the maintenance cost is only 1/3-1/2 of that of traditional brick walls, allowing users to save a significant amount of manpower and financial investment.

Allowable vertical load and heat transfer coefficient of PROPANEL EPS sandwich roof panel (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/㎡·k) |

Weight |

Load P=KN/m2 |

0.6 |

0.8 |

1 |

1.2 |

1.5 |

|

50 |

0.64 |

10 |

L(m) |

6.5 |

5.8 |

5.1 |

4.6 |

4 |

|

75 |

0.43 |

10.45 |

L(m) |

7.8 |

7 |

6.2 |

5.6 |

5 |

|

100 |

0.32 |

10.9 |

L(m) |

9.5 |

8.5 |

7.5 |

6.8 |

6 |

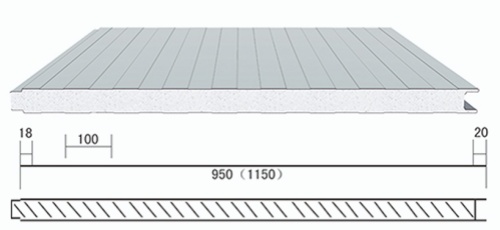

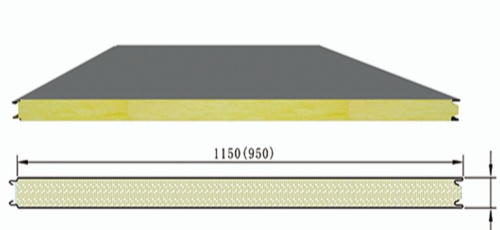

3 Joint Type for EPS Sandwich Wall Panels

There are 2 kinds of lap type for EPS Wall sandwich panel: one is cap type, another is overlap type.

Pictures are as below:

Socket Type 950 1150 Wall Panel

S-Socket Type 950 1150 Wall Panel

4 Application of EPS Wall Sandwich Panel

The EPS wall panels are widely used in the construction industry due to their lightweight, insulation, soundproofing, and fire-resistant properties.

In industrial buildings, they are the preferred choice for industrial plant walls. Their light weight can reduce the load on the main structure and lower costs. Good insulation performance can reduce the energy consumption of air conditioning and heating, making them suitable for workshops with temperature requirements. Moreover, they are easy to install, which can shorten the construction period and meet the needs of enterprises for rapid production.

In civil buildings, they are mostly used for low-rise residences, rural self-built houses, and prefabricated houses. The exterior walls have strong sound insulation, improving the living comfort; the interior walls can reduce the thickness of the walls and increase the usable area of the interior. Adding flame retardants, they reach B1 fire resistance level, comply with fire safety standards, have strong weather resistance, and can reduce maintenance costs later.

In public buildings, they are commonly found in temporary sales offices, temporary classrooms in schools, and isolation wards in hospitals. The factory prefabrication and on-site assembly method enables a 100㎡ building to be completed in 3-5 days. After dismantling, some panels can be reused, which is in line with the green building concept. Their insulation performance can maintain an appropriate indoor temperature.

In addition, they are used in cold chain storage to reduce heat loss and lower energy consumption; in agricultural greenhouses, they help maintain stable temperatures and are resistant to corrosion, able to withstand high humidity environmental erosion.

5 Project cases of EPS Sandwich Wall Panel

Project cases of EPS Sandwich Wall Panel--Brazilian logistics warehouse

Project cases of EPS Sandwich Roof Panel--Japanese electronic equipment factory

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on