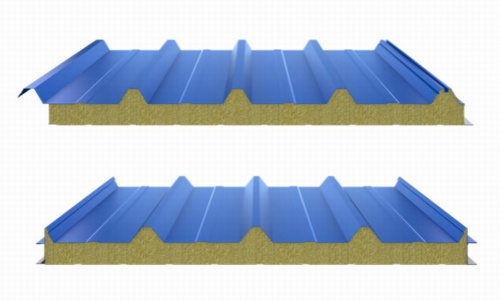

The 100mm Rock Wool Sandwich Roofing Panel offers top-notch fire resistance and thermal insulation with its dense rock wool core, cutting energy costs while blocking heat and noise. Built for industrial roofs, it delivers durability, lightweight strength, and easy setup, perfect for tough weather and heavy loads.

Item No :

ROCKROOF0001Order(MOQ) :

500 mPayment :

USD 30% PPColor :

CustomizedCore Material Density :

120 Kg/m³Shipping Port :

Qingdao, ChinaLead Time :

30-45 daysProduct Origin :

Shandong, China

|

Specifications |

|

|

Type |

100mm Rock wool Sandwich Roofing Panel |

|

cDensity |

Rock wool: 50~200 kg/m³, PU Sealing: 40 kg/m³ |

|

Thickness |

50/75/100/120/150mm |

|

Metal skin thickness |

0.4~0.8mm |

|

Panel Effective Width |

1000mm for wall and 950/1000mm for roof |

|

Skin material |

PPGL, PPGI, Stainless, Steel, Aluminum coil |

|

Pre-painted |

PE/SMP/HDP/PVDF etc. |

|

Fireproof Grade |

A |

|

Thermal Conductivity |

0.04~0.055 |

|

Temperature Range |

800℃ |

|

Length |

Max 11.9m or Customized. |

|

Customized design is welcomed. |

|

Fire Safety Excellence

The Rock Wool Sandwich Roofing Panel uses a Class A non-combustible rock wool core from volcanic sources, providing over 2 hours of fire resistance in tests. This protects structures like factories and schools from flames. Production bonds the core between steel sheets under pressure for tight seals. Quality checks include burn simulations and heat scans to confirm performance, ensuring safe roofs for busy sites.

Durable Build and Strength

With density from 80kg/m³ to 150kg/m³—often 120kg/m³—the Rock Wool Sandwich Roofing Panel hits compressive strength of ≥150KPa. Steel layers shield against rain, wind, and daily stress. Manufacturing presses materials evenly for no weak spots. Inspections test load bearing and weather exposure, verifying panels hold up in storms without cracks or bends.

Insulation and Green Benefits

The Rock Wool Sandwich Roofing Panel achieves thermal conductivity of ≤0.043W/m·K with fine fibers, or ≤0.025W/m·K with PU edges, saving energy year-round. Recyclable inorganic parts cut waste. Prefab design covers 600-800㎡ daily. Labs check insulation value and eco impact, making it a smart choice for low-cost, quiet roofs in homes or plants.

Allowable vertical load and heat transfer coefficient of PROPANEL new model fireproof rock wool sandwich roof panel with pu sealing (allowable deflection f ≤ L/240)

|

Thickness (mm) |

Heat transfer (W/m2k) |

Weight (kg) |

Load P=KN/m2 |

0.60 |

0.80 |

1.00 |

1.20 |

1.50 |

|

50 |

0.75 |

15.74 |

L(m) |

3.78 |

3.31 |

2.98 |

2.71 |

2.41 |

|

75 |

0.53 |

18.68 |

L(m) |

4.83 |

4.21 |

3.76 |

3.42 |

3.01 |

|

100 |

0.41 |

21.62 |

L(m) |

5.77 |

5.02 |

4.47 |

4.04 |

3.55 |

|

150 |

0.31 |

27.51 |

L(m) |

7.53 |

6.54 |

5.82 |

5.26 |

4.61 |

Note:0.5mm outer steel sheet and 0.4mm inner steel sheet.

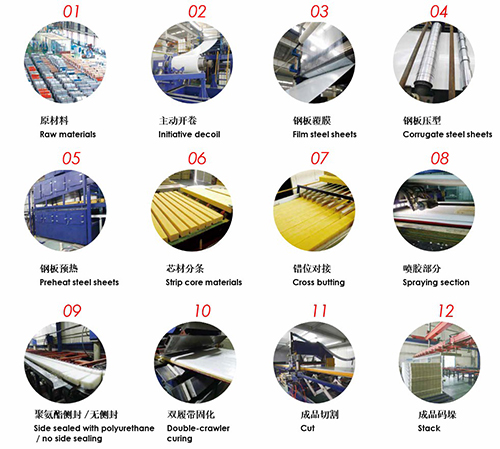

Initial Preparation Steps

The production of the 100mm Rock Wool Sandwich Roofing Panel starts with automated uncoiling of steel coils, followed by protective film coating for scratch prevention. Sheets get profiled into waves for added rigidity. Preheating prepares surfaces for bonding, while rock wool strips are cut and layered crosswise for uniform density. This ensures strong thermal insulation and fire resistance, key for safe industrial roofs.

Bonding and Curing Process

Adhesives spray onto preheated sheets, then high-density rock wool cores insert between them. Panels enter a double-track oven for even heating and pressure, forming a solid laminate. Optional PU edge sealing adds weatherproofing. Strict checks measure bond quality and core alignment, confirming durability and energy efficiency for long-term use in commercial buildings.

Final Assembly and Quality Assurance

Panels cut to exact lengths on a continuous line, then stack automatically for handling. Packaging secures them for transport. Tests verify flatness, load capacity, and fire endurance over 2 hours at 100mm thickness. Rock wool cores also absorb sound, reducing noise in factories. This procedure yields reliable panels for residential and warehouse roofs.

4 Project cases of 100mm Rock wool Sandwich Roofing Panel

Project cases of Rock wool Sandwich Roof Panel--Australian Animal Husbandry Base 20000㎡ in 2018

5 Honors and Certifications of Propanel

FM Certification for Tough Conditions

Propanel's Rock Wool Sandwich Panels earn FM certification for strong wind resistance up to 150 mph and impact tolerance in storms. The rock wool core at 100mm thickness blocks fire for 2 hours, tested in labs for real-world factory loads. Production uses pressure bonding for tight layers. Checks include wind tunnel runs and drop tests, confirming panels hold up in warehouses without cracks.

CE Mark for EU Compliance

The CE certification on Propanel's Rock Wool Sandwich Panels verifies safety, health, and eco rules for European builds. Panels feature rock wool cores that absorb noise by 30 dB, cutting shop sounds. Making involves clean-room assembly for no contaminants. Quality steps test thermal flow at 0.043 W/m·K and material purity, ensuring green roofs for offices last 30 years.

UL Approval for Fire Safety

UL certification highlights Propanel's Rock Wool Sandwich Panels for top fire block and overall guard in high-risk spots. At 50mm rock wool, it stops flames for 1 hour; thicker versions extend protection. Process seals edges with adhesives under heat. Inspections use flame spread meters and strength pulls, proving panels safe for schools and plants with low upkeep.

6 FAQs for Propanel 100mm Rock wool Sandwich Roofing Panel

1. What are the disadvantages of a sandwich panel roof?

Sandwich panel roofs may face corrosion, require maintenance, and have limited design flexibility. Propanel ensures durability and weather resistance.

2. Is rockwool good for roof insulation?

Yes, rockwool offers excellent thermal and fire resistance for roofs. Propanel’s rockwool panels enhance energy efficiency.

3. What are the risks of sandwich panels?

Risks include moisture damage, fire spread if not certified, and structural wear. Propanel panels are fire-resistant and durable.

4. Are sandwich panels load bearing?

Yes, sandwich panels can be load-bearing with proper design. Propanel ensures strength for structural support.

5. Is sandwich panel waterproof?

Sandwich panels can be waterproof with sealed edges. Propanel uses PU sealing for moisture resistance.

Copyright @ 2026 CHENGDU PROPANEL TECH CO., LTD. All Rights Reserved.  Network Supported

Network Supported

Sitemap / Blog / XML / Privacy Policy

Hi! Click one of our members below to chat on